3D machine vision system for measuring and quality control of billet geometry at Sidenor

Solid Machine Vision continues to develop advanced quality control systems with machine vision for steel processing plants. On this occasion, we have implemented a 3D system for measuring and quality control of billets in Sidenor – Aceros Especiales, in its Basauri plant. This company is a leader in the steel sector and has highly specialized facilities that are joining the challenge of digitalization and automation to provide suitable solutions to all industrial sectors that demand steels with high demands for service and quality.

The 3D System, developed with machine vision, performs the dimensional inspection of the continuous casting billets to control rhomboicity and bulging. In parallel, the system reads the DataMatrix/OCR of the part to trace that billet.

Due to the environmental conditions, the project requires a static and robust set without external moving elements, which has two static cameras, DataMatrix lighting and a laser with rotation on its axis, designed by us specifically for this project, which allows to inspect on metal at high temperature.

Industrial software and web console

Like many projects we carry out, this one also has its own characteristics and requirements given by the costumer. So in addition to having industrial software, developed and customized by Solid Machine Vision for image processing, analysis and data export, Sidenor raised the need to implement a web interface.

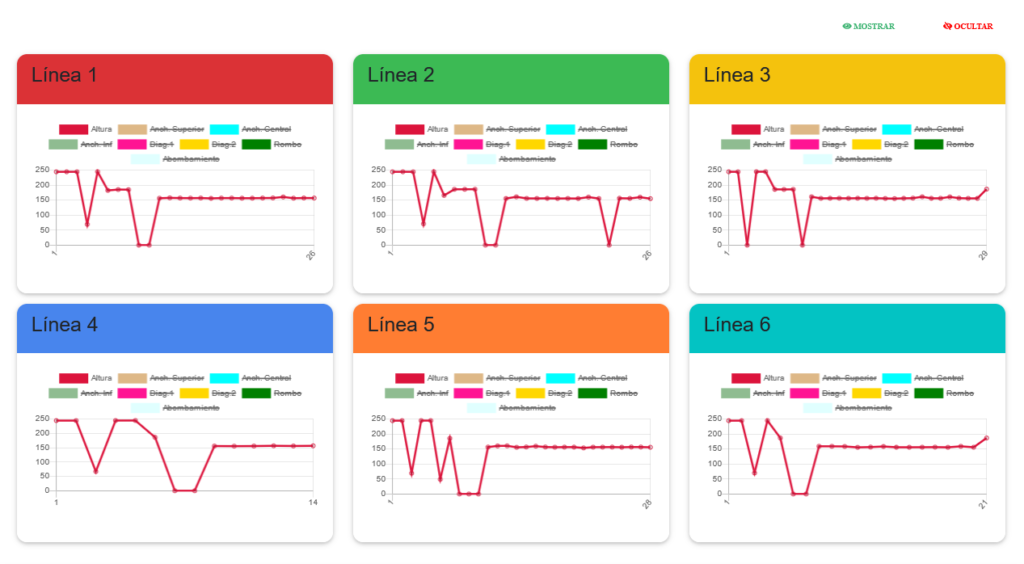

This web interface allows the consultation of the generated data with the possibility of visualization of geometric trends, export of data from the web and other advanced options. In this way, it is easier for the operator to follow the evolution of the data in real time.

We know that quality control in steel mills is very important and our customers seek to improve efficiency, optimizing their production processes.

For all these reasons, in Solid Machine Vision we strive every day to meet the needs of our customers and overcome with the best machine vision techniques, the challenges currently posed by the fourth industrial revolution or industry 4.0.

At Solid Machine Vision we offer turnkey solutions adapted to our costumers and their projects, offering advice without obligation. In addition, we develop specialized and customized technological software according to the user’s requirements.

If you want to know more about machine vision solutions for your company or project, contact us.